Whatsapp us

Whatsapp us

En News Center encontrarás una amplia selección de noticias interesantes e informativas de ECOPOWER.

Feb / 25, 2026

Ecopower to Exhibit at Three Major European Industry Events in 2026

Feb / 11, 2026

Ecopower Pre-Chinese New Year Shipment Rush: Ensuring Timely Delivery of All Products

Dec / 05, 2025

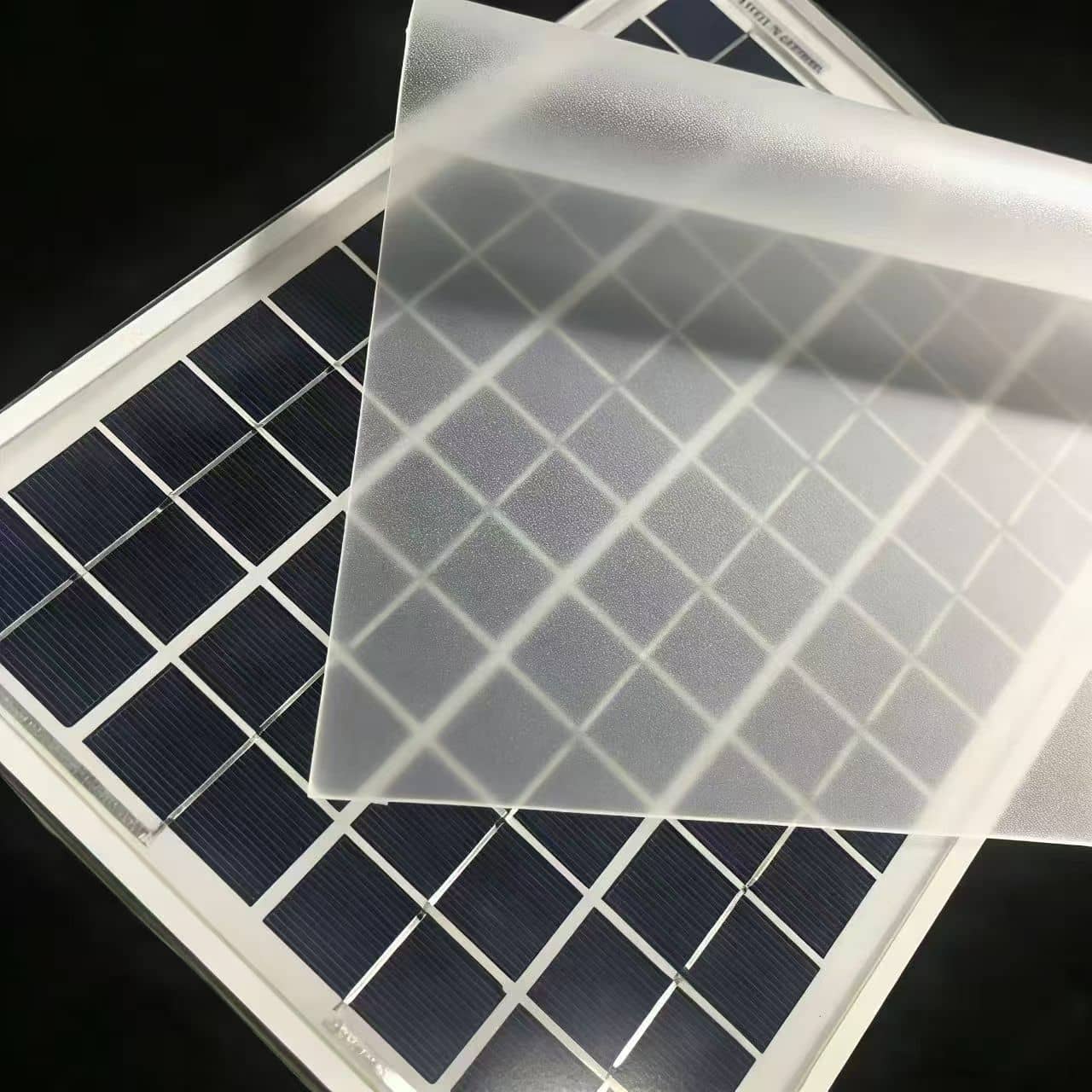

Potential Application of Ecopower Crosile®-7270 in Photovoltaic Encapsulation: Reinforcing Interfaces for Long-Term Reliability

Sep / 30, 2025

Viniltriisopropoxisilano Ecopower (Crosile-173): El aditivo clave para una adhesión superior y una durabilidad excepcional

Sep / 19, 2025

Ecopower celebra su exitosa presentación en RubberTech 2025: Las innovaciones en agentes de acoplamiento y resinas de silano atraen la atención de la industria mundial.

Aug / 21, 2025

Ecopower en la exposición de adhesivos y selladores RubberTech y ASE CHINA 2025

Aug / 06, 2025

Ecopower le invita cordialmente a asistir a la 23.ª Exposición Internacional del Nuevo Centro Internacional de Exposiciones de Shanghái (SNIEC).

Jun / 06, 2025

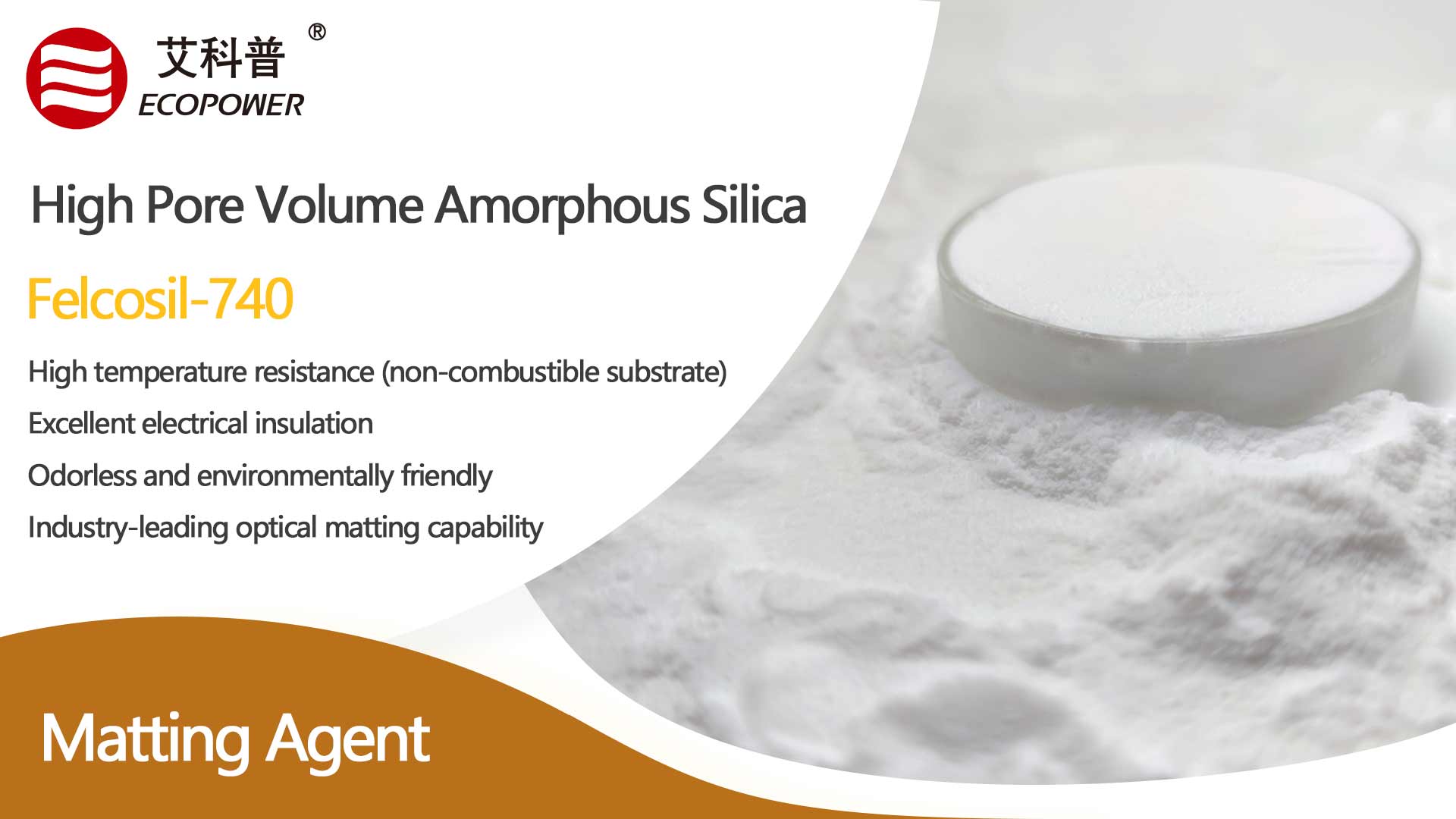

Sílice amorfa Ecopower Felcosil-740: Relleno mateante de alta eficiencia para recubrimientos | Tecnología sol-gel

May / 22, 2025

Ecopower (Yongxiu) New Material Co., Limited obtiene la certificación Ecovidas Plata

Apr / 29, 2025

Ventajas principales de la resina HY-9100RM: diseñada para aplicaciones de señalización vialmóvil/veloz : +86 13802793127

WhatsApp : +8613802793127

Correo electrónico : sales@ecopowerchem.com